Case Sharing-Hydrogen storage tank

Case Sharing-Hydrogen storage tank

With our country's strong support for environmental protection of new energy in recent years, the development of hydrogen energy has reached a new level, of which hydrogen storage tank is an important part. The hydrogen storage tank has certain designability and portability, which is conducive to daily transportation and assembly. The domestic hydrogen tank development is still in a primary state. It means there are many problems to be solved, such as the relevant standards to be formulated and improved. However this is a very promising field!

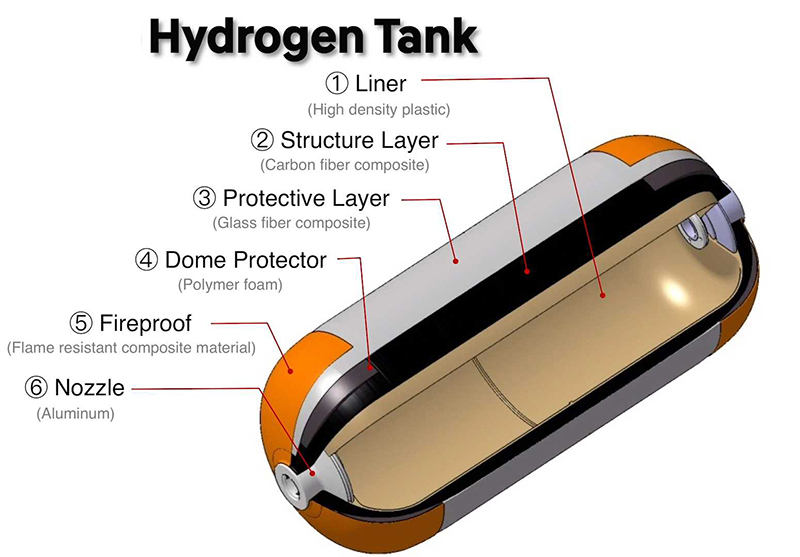

composition and structure

The rotational molding process is one of the main processes for making the inner liner (plastic ) of hydrogen storage tank. General requirements of lining include resistance to hydrogen permeability, temperature resistance, lightweight, technological, material modification and so on. We currently use modified materials, like XLPE, PA, for inner liner production.These materials have high accuracy requirements for equipment and mold.

As early as 2018, a number of new energy companies and universities with related majors in China have launched multi-aspect cooperation with our company regarding the hydrogen storage tank tank. Our company mainly provides the molds and equipment required by customers, as well as the research and development support for customers based on the relevant experience and knowledge in the field of rotational molding.

We help customers develop target products by analyzing product forming, parting mode, demulding difficulty, product shrinkage, rotating arm placement, equipment selection and so on. Now the products have been tested in various aspects. And we have also received hydrogen tank mold and equipment development commission from European countries!

Advantages of the inner liner

01.One piece forming, no welding

02.Lightweight

03.Controllable wall thickness

04.Strong process design

05.Different materials can be used to test temperature resistance, permeability, resistance to deformation, etc.

06.Insertable insert

07.Long service life

中文简体

中文简体 English

English Русский язык

Русский язык España

España عربي

عربي